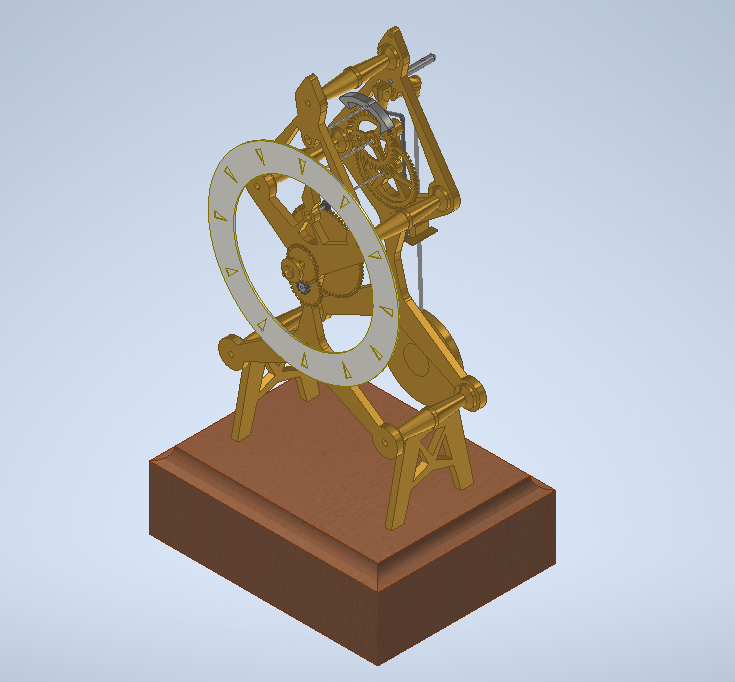

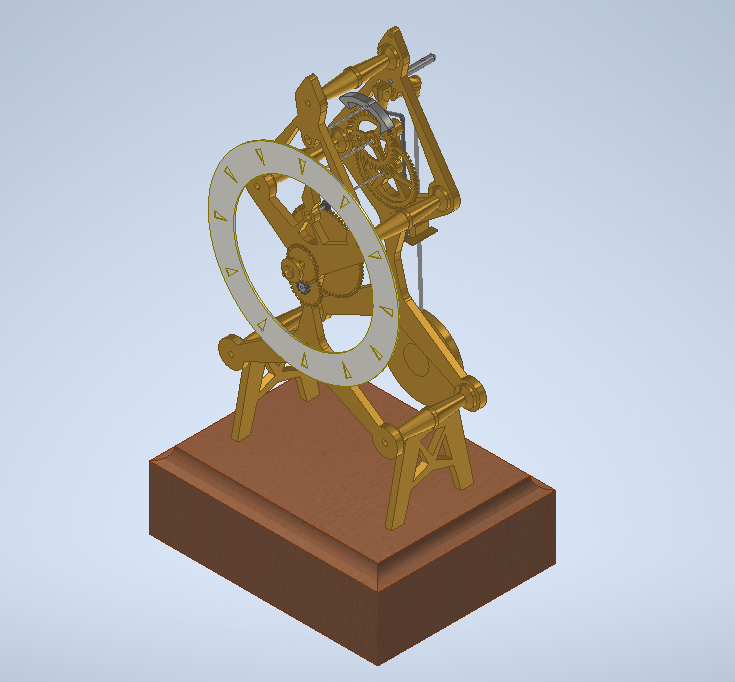

Mechanical Clock

Building a mechanical clock completely from stock material using manual machine tools. This project is ongoing.

Building a mechanical clock completely from stock material using manual machine tools. This project is ongoing.

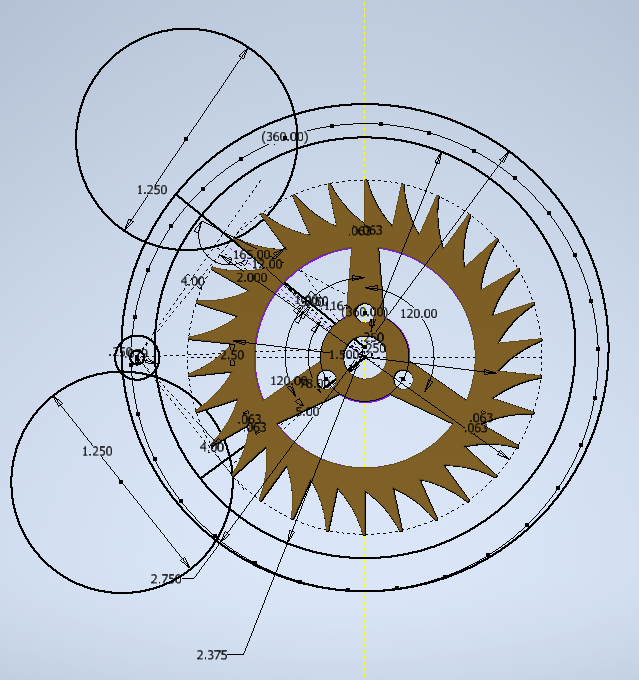

The escape wheel is the defining mechanism of a mechanical clock.

It simultaneously tracks the isochronic swing of the pendulum, translating the swing into the

motion of the clock hands, and provides additional energy to the pendulum with every swing to

keep it moving.

A recoil escapement was chosen for it's relative simplicity and forgiving

nature. To design the escape wheel, I followed the British Horological Institute's guide that

has been the same for nearly 100 years. The layout for the final escape wheel is shown on the

left.

After completing the bulk of the design, it seemed that the most

challenging part of the clock manufacture would be the gears (called wheels for the larger

driving gear and pinions for the smaller driven gear). One trait of mechanical clocks that is

uncommon in the modern world is that the large gear is usually driving the small gear. Because

of this, the obsolete cycloidal tooth form is more optimal than the modern involute gear form.

The mesh efficiency of gears is particularly important when you desire a clock to run on a

single wind for a week or more. This is all to say that gear cutters for the necessary gears are

not available for any reasonable price off the shelf.

So, as a proof that the clock could

be manufactured, the first part to be made was the gear cutter pictured to the left. The profile

approximates the inverse of the involute tooth form and the necessary angular geometries are

machined into the tool steel before it is hardened to actually cut gears. This is my next step.